We have noticed two very distinct healthcare design trends over the last year and a half.

First, the COVID-19 pandemic and the accompanying influx of patients highlighted the need for flexible spaces. As a result, there has been a big push for modular construction and design, allowing facilities to accommodate their community’s changing needs.

According to a survey published by the U.S. Department of Health and Human Services, COVID-19 significantly impacted healthcare spaces. The survey states, “To manage patient flow and hospital capacity, some hospitals were providing ambulatory care for patients with less severe symptoms, offering telehealth services when possible, and setting up alternate facilities such as fairgrounds, vacant college dorms, and closed correctional facilities as additional spaces for patient care.”

Modular & Flexible Design

The layout and construction of that temporary and added space demanded modular and flexible design elements and easy-to-install plumbing accessories and fixtures. It was a trend that caught on in permanent healthcare facilities and has changed how those spaces are now being designed.

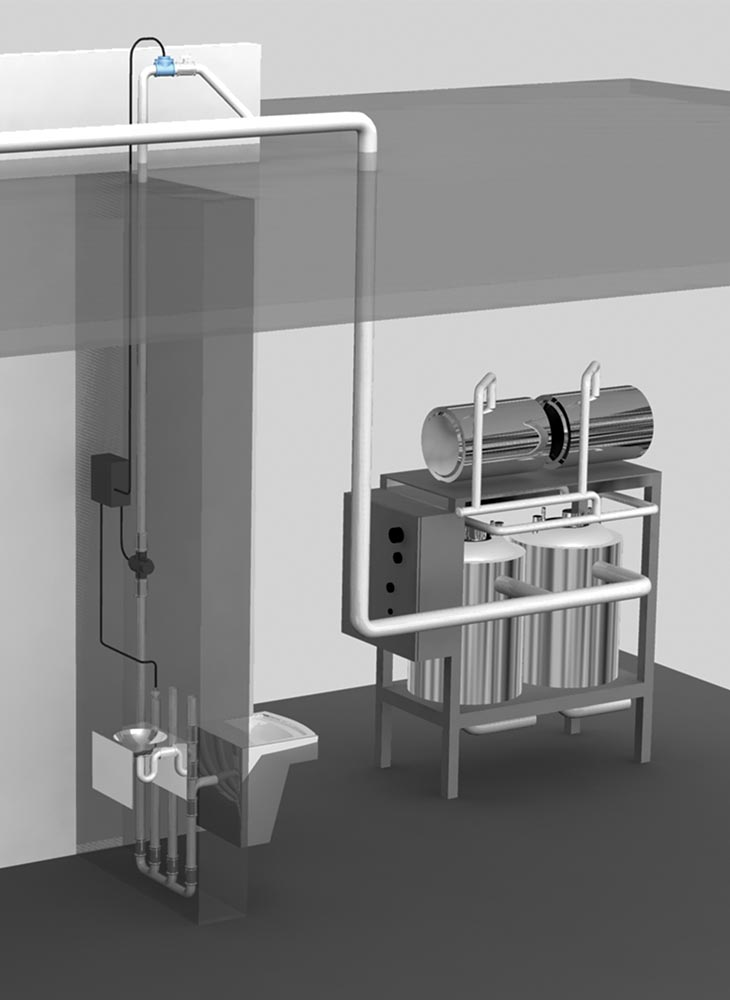

The need for modular, flexible spaces has also brought our sister company, AcornVac, Inc., to the forefront. Because vacuum plumbing does not require gravity, piping can be routed vertically or horizontally. Architects, contractors, and facilities all benefit from the ease with which the system can adapt to the facility’s changing needs. Moving plumbing fixtures with the AcornVac® system is as easy as moving furniture—and with as little disruption. As a bonus, it reduces the spread of bacteria, is easy to maintain, provides protection from waste piping leaks, and at just ½ gallon of water per flush, it is far more cost-effective than conventional plumbing.

The pandemic brought to light a significant design problem in Emergency Departments and behavioral healthcare facilities. Providers quickly discovered a need to quarantine people infected with COVID-19 from the rest of the patient population but did not have a good way to do it.

As a result, there was a reduction in the number of people seeking treatment for accidents, heart attacks, strokes, and other life-threatening emergencies. Unfortunately, these patients were too scared to enter the Emergency Department when the space was overwhelmed with COVID patients.

CHI Health Good Samaritan was in the midst of construction for a new Emergency Department when COVID hit. The new design developed back in 2016 included screens and more isolation for patients. The thinking even back then was that private exam rooms with doors and walls would help when dealing with infectious diseases like SARS and Ebola.

The pandemic showed how necessary those changes would be. So in addition to better isolation for patients, CHI Health Good Samaritan added more screens at the hospital entrances during the pandemic, and they will remain in place.

And speaking of entrances and lobbies, the current COVID-19 pandemic is prompting big changes in the design of healthcare lobbies to protect patients, staff, and families. Some facilities are significantly reducing the footprint of these communal areas to discourage mingling and make way for more treatment areas.

Other changes to lobbies and throughout the facility include flexible seating areas, furniture with antimicrobial finishes and hands-free doors, elevators, faucets, and flush mechanisms. And, per a report in MCD Magazine, one hospital turned its lobby into a triage area fully equipped with medical gas, vacuums, and power hidden in lobby columns.

Layered Systems Approach to Plumbing

The second trend is hospitals and behavioral health facilities are adopting a layered, or systems approach to water management. It is a smart way to fight infection in all facilities but is also a way to enhance control and patient safety in behavioral healthcare without being obtrusive.

What is a systems approach to infection control? Facilities that are embarking on this trend are paying attention to the inherent structure of the plumbing systems and what is happening behind the walls. Just as healthcare providers strive to stop the spread of disease at its source in the body, so too are facilities trying to stop the source of waterborne viruses and bacteria before they get out of control. In fact, effective January 1, 2022, The Joint Commission will require documented water management programs that address Legionella and other waterborne pathogens.

For example, stagnant water was a significant issue for facilities experiencing downtime due to the cancellation of elective surgeries in early 2020. This problem can and should be solved with a systems approach.

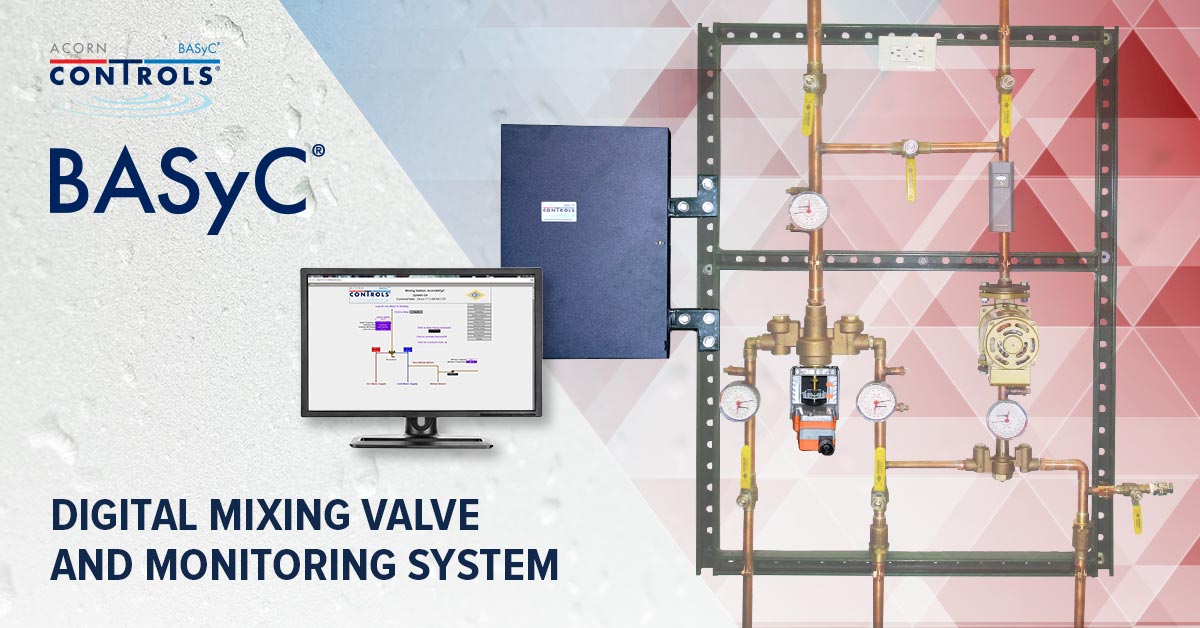

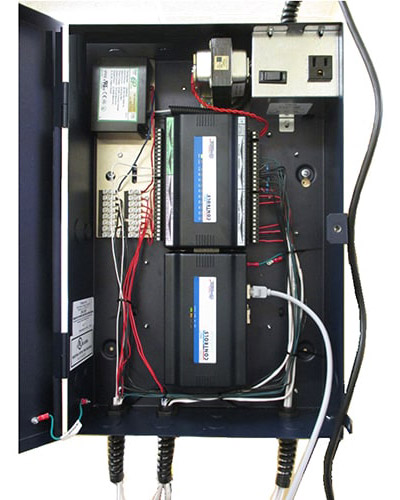

Many facilities are going digital for their recirculating hot water systems. On our side, we are seeing more and more healthcare facilities and engineers specifying ConTrols® digital mixing valves and monitoring systems.

The advantages you get from these systems benefit both the facility and the installer. Any digital system you specify should include:

- Automatic alarms when outlet temperatures fall outside your water management plan specifications

- A sanitization mode to help combat Legionella easily and quickly

- The ability to communicate with your building automation system (BAS), if necessary

- The ability to eliminate temperature creep and loop balancing issues

That covers the basics, but you also want to look out for systems that are easy to install and maintain. That will save you time and money on the initial installation and maintenance costs for years to come. A rack-mounted/pre-engineered system will:

- Eliminate piping issues

- Prevent substitution of low-quality and incompatible parts

- Prevent omission of checks such as crossflow

- Help you troubleshoot the system during a power outage or sensor failure

Let’s be honest. If we can get notifications on our phones when a package has been delivered to our homes, shouldn’t we also be able to communicate with something as important as a hospital water system?

A good digital mixing valve system will notify your facility team should there be an issue with the hot water system, no matter when it occurs. For example, should something happen in the middle of the night beyond an onsite maintenance team’s ability to diagnose, the appropriate engineer would receive an alert and take initial steps to diagnose and fix the problem right from their home computer, tablet, or smartphone. No one knows better than healthcare workers that every second saved can have a massive impact on outcomes.

Dialysis Boxes a Potential Source of Stagnation and Legionella

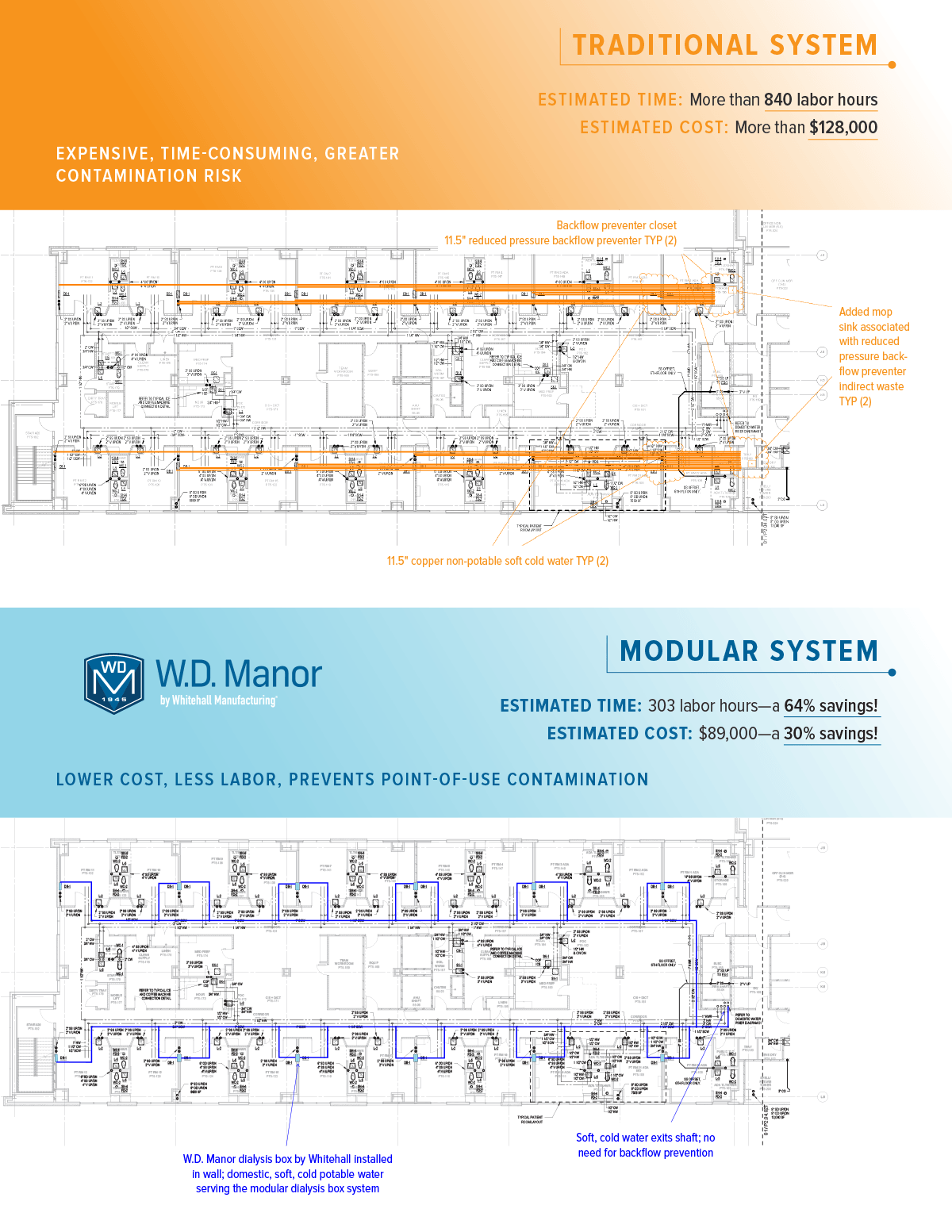

Let’s talk about another potential, yet often overlooked, source of stagnation and potential Legionella growth in a facility—dialysis boxes. These are typical in a healthcare facility and are generally used by patients who are likely to be immunocompromised and therefore have a higher risk of infection. Traditionally these boxes were housed in remote locations in the hospital requiring compromised patients to be moved through the hospital for treatment.

Following the trend of a systems approach to infection prevention, mobile dialysis treatment is being taken to the patient. But infection prevention doesn’t stop there.

Whitehall has been manufacturing dialysis boxes for years, but when W.D. Manor released their all-inclusive units, we sat up and took notice. Each dialysis box includes an integrated reduced pressure backflow preventer. This eliminates the need to pipe back to a shared backflow preventer and eliminates the possibility of cross-contamination that can arise from that arrangement.

Their boxes were the best dialysis units on the market because they were designed by mechanical contractors with a deep knowledge of their market. So, we formed a partnership with them to manufacture and sell their invention—the industry’s only prefabricated modular dialysis supply wall box.

It is important for us to get the word out to all our customers—architects, engineers, and facilities—that this new box would be a far more cost-effective choice than traditional dialysis boxes, but even more importantly, increases patients’ safety by protecting the water source at the point of connection.

A Layered Approach Provides Safety & Security in Behavioral Health

A layered approach brings more control and safety to behavioral healthcare that goes beyond infection protection. We have been seeing an uptick in facilities and architects asking about options for managing water in individual rooms to stop intentional flooding and other plumbing issues.

We can provide a complete bathroom that meets all behavioral care needs. On the “outside” of the wall is the BestCare® Dignity Suite™ collection. This curated collection of ligature-resistant bathroom fixtures and accessories creates a peaceful and well-balanced environment. At the same time, the Dignity Suite of products is stylish and sleek while simultaneously protecting patients’ safety.

Then, “inside” the wall, you have vacuum plumbing. Not only does a vacuum system drastically reduce system blockages, but if they do occur, they can be identified at the fixture where the problem is occurring for a quick fix.

Adding Acorn® Master-Trol® electronic valve system provides another layer of safety, allowing you to monitor and maintain control over water usage and save water at the individual fixture level. It prevents patients from flushing toilets excessively, ensures faucets are not left running and helps manage shower usage. Because this level of control is concealed within the wall and at a nursing station, it is inaccessible to patients and will not impede the therapeutic healing environment.

Get Your Architects & Engineers Involved Early

Keep in mind that a layered approach to water management and safety requires facilities to bring their plumbing engineers in earlier in the design process. This isn’t like choosing a sink or a faucet. A systems approach requires spatial planning, and plumbing engineers need to work with the architects and designers. In fact, you should be bringing your architects and designers into the process earlier as well.

Just about every architect and designer we speak with all say the same thing: they want to be involved in renovations and new construction, ideally before the program is even defined. Early architect and designer involvement helps to ensure you are getting the best products delivered when the plumber needs them, speeding up construction time and lowering costs. But even more critically, architects and designers have a broad body of experience, know what works best, and have the research to back up their recommendations. They may even be able to introduce a service model that is a better financial bet.

If you’ve read about or worked on new modular and flexible spaces, we’d love to hear about it and possibly highlight the project in one of our upcoming newsletters. If you have questions about water management plans and the new Joint Commission requirements, let us know, and we will get you in touch with the right people to help you with that.

And of course, if you want more information on vacuum plumbing, the prefabricated W.D. Manor All-in-One Dialysis Box by Whitehall, digital mixing valves and monitoring systems, or any of our modular, design-friendly ligature-resistant healthcare products, don’t hesitate to get in touch with us today!

If you have not already, be sure to sign up for our quarterly newsletter. We’ll be back with another fantastic industry expert interview this winter. Meanwhile, you can catch up on past interviews on our blog.